3 questions to help logistics managers reduce cost pressure

Experts answer questions about warehouse space, partnerships and economical packaging for logistics businesses.

FreightWaves kicks off Global Supply Chain Week, which kicks off March 7 with the keynote "Creating Flow and Removing Space in Logistics" by Julian Van Erlach, Senior Vice President in charge of the FabFitFun supply chain. He is also an inventor holding more than 10 patents related to logistics, used by FabFitFun, Amazon....

In the keynote, Van Erlach answered three questions logistics leaders should ask to leverage the transportation network and reduce costs for customers.

.png)

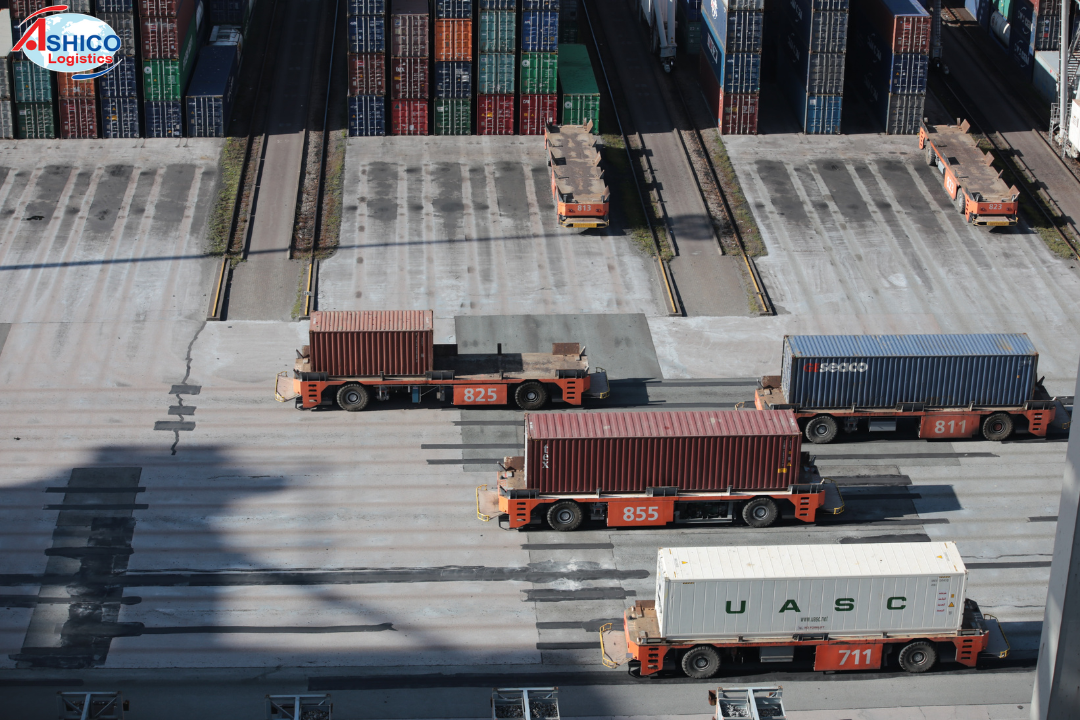

Reducing transportation costs is the need of most businesses

Should you invest in warehouse space?

Mr. Van Erlach describes the risk of capital investment in warehousing and the benefits of leveraging a network of 3PL logistics service providers. Specifically, to avoid costs for unnecessary services, he suggested businesses consider the needs of customers and their ability to meet them.

For example, when warehouse vacancy rates decreased and storage costs skyrocketed, FabFitFun began to find ways to make the most of that space. "FabFitFun wants to be a 3PL company. In addition to managing our own volume, we are attracting potential customers because FabFitFun has comprehensive logistics capabilities," he shared.

There are more than 1 million companies smaller than FabFitFun registered for management cooperation. That shows that third-party logistics networks allow companies to develop more flexibly.

What will the partnership be like?

The Covid-19 pandemic forced FabFitFun and many other companies to rethink their partnership strategies. "It's time to diversify logistics services. We've worked directly with every major last-mile carrier. It was the right decision as it was able to help the company deliver all of its goods on time." .

In particular, the biggest benefit of the partnership is helping the parties optimize shipment sizes. "We consider the requirements and attractions of service providers and design according to customer requirements. From there, logistics companies can reduce the harm of transportation to the environment and have competition. strong charges".

How to cut packaging costs?

Mr. Van Erlach explained a company can reduce shipping costs by meeting a carrier's packaging requirements. In addition, negotiating with product suppliers about shipping strategies can also lead to greater cost savings.

"We found inefficiencies in the packaging design. For example, manufacturers often bundle plastic straws with the product and that is not necessary," he said.

In addition, shared warehouse use can make it easier for carriers to maximize truck space and save shippers. "This is a combination of strategies sought by many businesses. They always ask the question how to transport more goods but still make a lot of profit. Shared warehouse and transport is the solution. ", confirmed Mr. Julian Van Erlach.

Phi Hung (according to FreightWaves)